Travel Diary Part 2 - Life at the Daniel Alain Factory

I must admit that a couple of years ago, before I became the Content Manager at Daniel Alain, I had no idea how wigs were made and I’d certainly never given a wig factory’s working conditions, health and safety policy, or sense of community a second thought.

If you’re curious about the industry standard, search for ‘human hair wig factory’ on Youtube as I did when preparing for my visit to the Daniel Alain factory in Weihai, China. You’ll find plenty of videos featuring factories with less than desirable working conditions at best, and a complete disregard for worker safety at worst. While I can’t tell from the videos, I can only assume that there’s a lack of proper ventilation, particularly for workers working with chemicals and dyes or protective clothing.

In an industry so often driven by cutting costs, the safety of the workers seems to be regularly compromised.

I’ve never been in any kind of factory before, and although I know our brand has a good reputation and had only heard good things about our factory, I braced myself for what we might find there.

After a long (very long) flight to Weihai, China we arrived on a sunny afternoon and were greeted with blue skies and the company driver holding a sign with our names on it. He took us to our hotel where we were able to stretch our legs and relax a little before the busy week ahead.

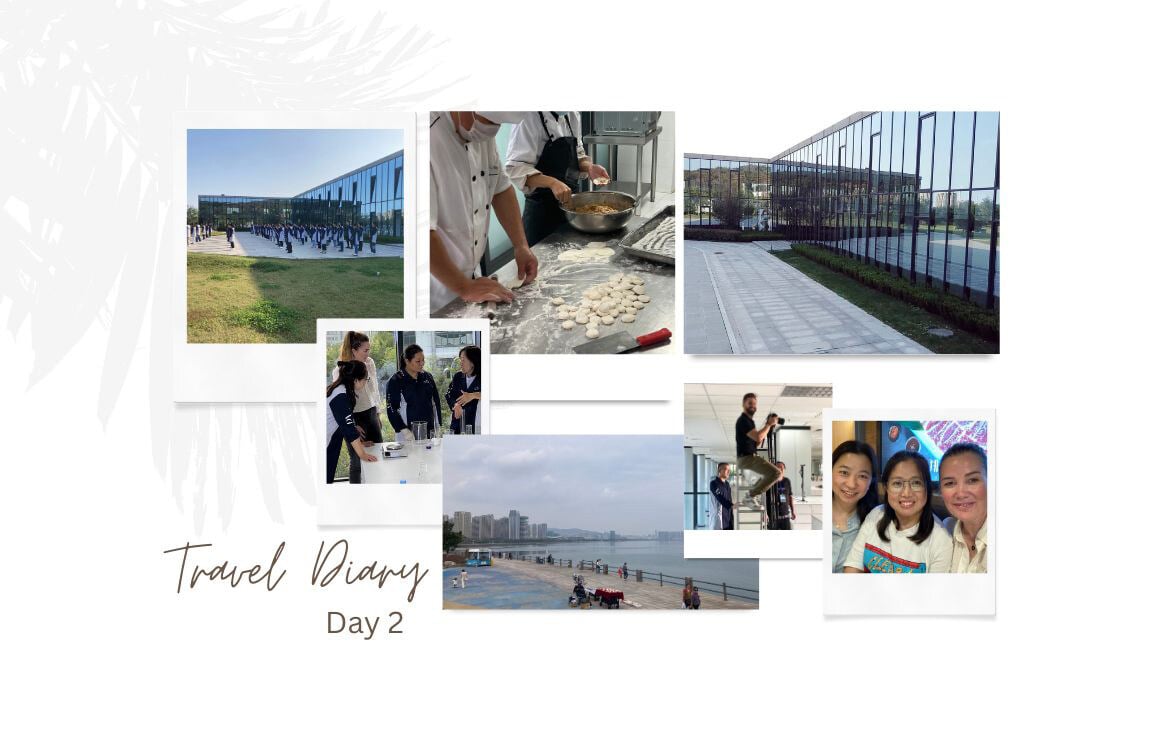

With a population of around 3 million people, Weihai is considered to be a relatively small city that grew from a humble fishing settlement. These days, the city hugs the coastline and boasts pretty beaches flanked by boardwalks, a busy highway with even busier traffic, and the usual tourist shops and restaurants that grace most seaside cities across the world.

With a population of around 3 million people, Weihai is considered to be a relatively small city that grew from a humble fishing settlement. These days, the city hugs the coastline and boasts pretty beaches flanked by boardwalks, a busy highway with even busier traffic, and the usual tourist shops and restaurants that grace most seaside cities across the world.

After a day’s recovery and sightseeing trip, Monday morning rolled around and we found ourselves pulling up to the factory ready to begin setting up for our first day of filming.

My first impression of the Daniel Alain factory was that its glistening glass facade was something more likely to house a museum of modern art or a large tech company that allows its employees to bring their dogs to work. From the outside, the building is beautiful. Immaculate and modern compared to some of the dumpier, run-down, traditional factory buildings close by, but also beautiful in its own right.

My first impression of the Daniel Alain factory was that its glistening glass facade was something more likely to house a museum of modern art or a large tech company that allows its employees to bring their dogs to work. From the outside, the building is beautiful. Immaculate and modern compared to some of the dumpier, run-down, traditional factory buildings close by, but also beautiful in its own right.

The building was designed by a Danish architect. From the outside the giant, cathedralesque windows reflect the abundant natural-light and the greenery in the hills and fields that surround it.

The inside is equally expansive. With an impressive entrance hall that invites you to ascend the sweeping staircase or proceed down the ‘grand hall’ and experience the ceilings that reach all the way to the roof. Natural light floods the factory. Wig-making is very precise, focused, detailed work and the design of the building feels intentional.

We started with a factory tour and the first thing that hit me was that everything was spotlessly clean and polished to perfection. It was a far cry from the wig factories I had seen on Youtube a few weeks before. Workers wear company uniforms to keep their own clothes clean. People working with bleach and dyes wear protective eyewear, aprons, and gloves. People working with adhesives wear respirators, and people working with loud sewing machines wear ear plugs.

The atmosphere is warm and industrious. People smile and wave shyly as we walk past their section, or giggle as we attempt to say “nǐ hǎo” (hello) in Chinese. Everyone seems focused on their work and everything feels safe, efficient, and precise.

From the very beginning, there was an emphasis on the need to train and retain skilled workers. Their ability to manipulate the materials and work their tools combined with their years of experience, are priceless. It was Daniel’s hope that by investing in the things it takes to make this one of the best places to work in the entire city of Weihai, he would create an environment that allowed workers to perfect their craft and to feel safe while doing so. Many of the workers have been with the brand for decades.

From the very beginning, there was an emphasis on the need to train and retain skilled workers. Their ability to manipulate the materials and work their tools combined with their years of experience, are priceless. It was Daniel’s hope that by investing in the things it takes to make this one of the best places to work in the entire city of Weihai, he would create an environment that allowed workers to perfect their craft and to feel safe while doing so. Many of the workers have been with the brand for decades.

One of the perks of working in this factory is the company bus. Though many people have cars or scooters that they drive to work, the company bus is provided for anyone who prefers to avoid navigating the chaotic daily commute through the city themselves. People live in tall, imposing apartment buildings that dominate the Weihai skyline. The bus picks them up and drops them off at the end of their road every morning and night.

A day at the factory begins with morning exercises, performed en masse, in the outdoor courtyard, surrounded by green grass and established trees. At first glance, this seemed foreign to me. The regimental rhythms of the synchronized exercises performed by a couple of hundred people to music played over a loudspeaker is certainly not how we start our day in the office in Southern California. But replace the disciplined stretches and movements with more gentle yoga poses, and the rhythmic music with something a little more meditative, and it’s not too far from something I’m more familiar with seeing.

Sidenote: to be clear, we also don’t start our days in the office with a yoga session, but it’s something I can imagine doing.

Lunch is provided and cooked on site by a team of chefs, and served in a beautiful cafeteria that looks more like the restaurant of a 5 star hotel. Later in the week, we would have the chance to film the chefs making dumplings, and the delicious good fortune to sample them.

Lunch is provided and cooked on site by a team of chefs, and served in a beautiful cafeteria that looks more like the restaurant of a 5 star hotel. Later in the week, we would have the chance to film the chefs making dumplings, and the delicious good fortune to sample them.

As the week went by, I couldn't help but reflect on the stark contrast between the wig factories I had seen on YouTube and the one I was experiencing firsthand. It was a reminder of what can be lost in the pursuit of cheaper products. The reality is, when brands cut costs, it often comes at the expense of those who make the products - the real men and women whose health, safety, and quality of life may be compromised.

It’s easy for us all as consumers to be tempted by lower priced products - but don’t we all have a responsibility to consider what those savings might truly cost? The conditions that workers endure, their exposure to harmful chemicals without proper safety measures, the environmental damage caused by dyes being put back into the water system are hidden behind every low-priced tag.

As I left the factory at the end of the week, the echo of laughter, the sight of workers boarding their bus home, and the warm camaraderie of shared meals lingered with me. I felt not only proud to work for a company that values its people, but also deeply aware of the choices we all make when purchasing a product.

Step Inside the World of Wig-Making

Seeing is believing, and we want you to experience it too. That's why we captured the journey on video, so you can get an up-close look at the skill and care that make our pieces truly extraordinary.

Head over to our factory video series to discover the magic for yourself. Watch how each wig and topper is brought to life, meet the talented craftspeople behind the scenes, and gain a deeper appreciation for the incredible work that makes our products stand out. You won’t want to miss it!

.jpeg)