Travel Diary Part 1 - Our Journey to the Daniel Alain Factory

As the Content Manager at Daniel Alain, I’ve had the enormous good fortune to travel all over the US with our Videographer, Grégoire Thiry. We’ve been able to interview real-life customers and retail partners to bring our readers articles and videos that truly resonate with anyone going through a hair loss experience of their own.

We’ve been honored that so many remarkable women have agreed to share their story with us and we’ve sat in awe listening to stories of their journey through chemotherapy, their battle with alopecia, or the realities of always having lived with hair that has never seemed full enough.

This work feels meaningful, important. Hair loss, and especially women’s hair loss, can feel isolating, and helping someone feel supported gives us a sense of purpose. We know that for the women we interview, sharing their story with us is a big deal and we never take it lightly.

For all the friendships we’ve made, the laughs we’ve shared, and the times we’ve all had to pull together to lug 10 tons of camera and lighting equipment up and down rickety warehouse stairs on a 90°F day (thank you Minneapolis!), we’ve also shed tears over painful memories and felt the enormity of watching someone find the courage to share their greatest vulnerabilities with us.

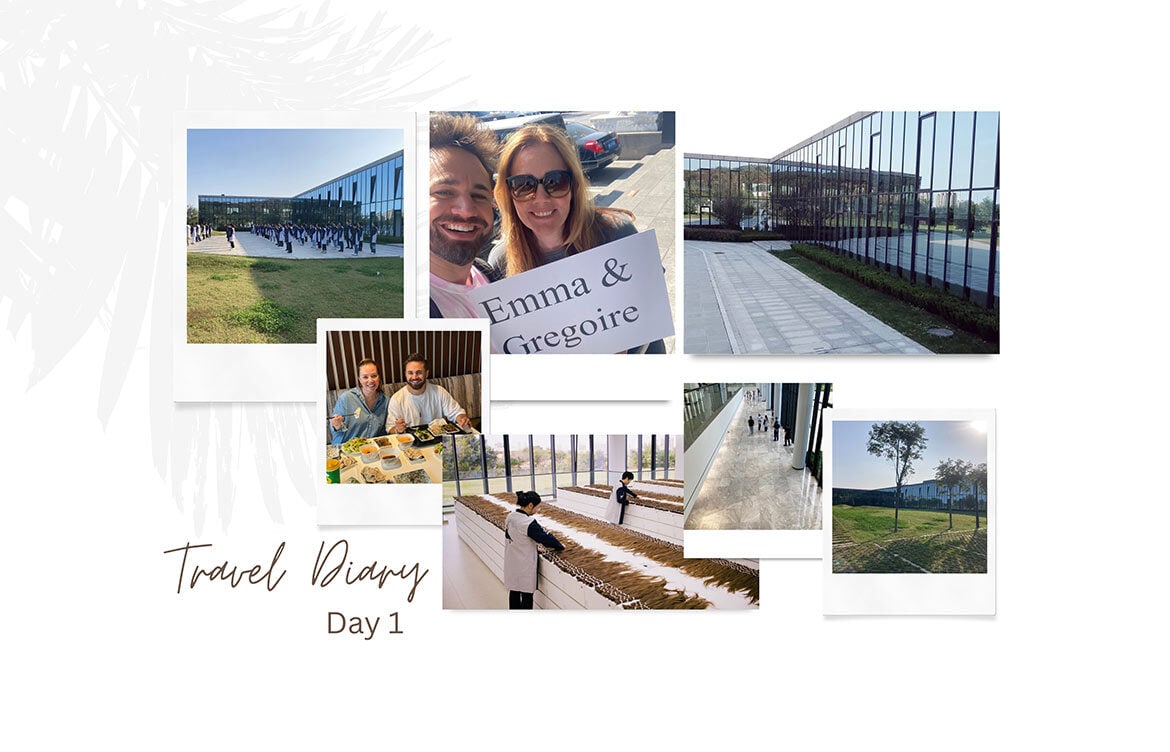

Our most recent work trip however, took Grégoire and I much further afield than Boston, Denver, or Minneapolis. This time we were tasked with visiting our factory in Weihai, China. And while we weren’t going to hear hair loss stories, or tales from a real-life wig-wearer, we were equally determined to find the story, and the meaning, in our work.

Our most recent work trip however, took Grégoire and I much further afield than Boston, Denver, or Minneapolis. This time we were tasked with visiting our factory in Weihai, China. And while we weren’t going to hear hair loss stories, or tales from a real-life wig-wearer, we were equally determined to find the story, and the meaning, in our work.

Our boss, Daniel Alain Hafid, owns a 90,000 sq ft manufacturing facility in China. If you’ve read some of my previous articles about Why Follea Wigs are the Best in the Industry you’ve likely already heard us brag about how rare it is for a wig brand to own their own factory and control every part of the manufacturing process.

The majority of other brands purchase their wigs pre-made from manufacturers and have no control over the manufacturing processes. This leaves them vulnerable to poor quality control, susceptible to inconsistencies in sourcing, and having no influence in how factory workers are treated.

A trustworthy company that values fair labor practices will have no hesitation showing off their facilities and demonstrating their commitment to transparency and ethical standards. This openness builds trust and ensures customers are supporting a company dedicated to integrity and responsible business practices.

Daniel Alain has created a safe working environment and processes that protect the integrity of our hair, ensure absolute consistency across our range of collections, and allow us to offer premium quality wigs and toppers year after year.

The Daniel Alain factory took 3 years to build. Weihai typically gets heavy snow over the winter months, and this significantly slows down construction work. Additionally, being a purpose-built factory designed to manage the unique needs of processing high-quality European human hair, every element was pondered over, planned, thought through, and intentional.

The Daniel Alain factory took 3 years to build. Weihai typically gets heavy snow over the winter months, and this significantly slows down construction work. Additionally, being a purpose-built factory designed to manage the unique needs of processing high-quality European human hair, every element was pondered over, planned, thought through, and intentional.

From the water filtration room that holds the giant tanks that purify the water used to wash and rinse the hair, to the overhead natural-light light bulbs so workers can see to perform the delicate task of ventilating the hair, this factory is a far cry from the industry standard.

Daniel built this factory from the ground up but he didn’t do it alone. He first employed a small group of people that later became his core team that would eventually run the day to day tasks of managing the factory in his absence. Then he invested in making his factory a great place to work in order to keep the skilled workers he attracted.

Daniel built this factory from the ground up but he didn’t do it alone. He first employed a small group of people that later became his core team that would eventually run the day to day tasks of managing the factory in his absence. Then he invested in making his factory a great place to work in order to keep the skilled workers he attracted.

This commitment to investing in people has meant that people are still working for the brand over 2 decades after starting. There’s no problem this team can’t solve or haven’t seen before. As a result, the factory has become a hub of craftsmanship and innovation, where the art of wig-making is elevated to the highest level.

Our visit was going to be an opportunity to see the wig-making process in action and to connect with the people who make our products possible. Anticipating hearing their stories, understanding their challenges, and celebrating their successes filled us with excitement for what was to come.

Experience the craftsmanship Behind the Scenes

There’s so much more to share about the incredible artistry and dedication behind our wigs and toppers.

We’ve captured every moment of the visit on video—an up-close look at the craftsmanship, passion, and precision that go into every piece we create. If you’re curious to see what happens behind the scenes, check out our factory video series to explore it all. Trust us, you’ll want a front-row seat for what’s coming next!

.jpeg)